TAPS - Turnaround Progressing System

Highlights Overview News Case Studies Videos Survey Results Blogs ExperiencePrimavera P6 Barcode Updating - Reduce Activity Statusing Time Up To 75%

- New Release of TAPS v11 - Mobile Enabled

- Built with HTML5 - Compatible with all browsers and mobile devices

- Fast and error-free updating of P6 activities

- Use less experienced or clerical staff for updating

- Fast and simple implementation with virtually no training required or help needed from IT

Latest Version - Highlights

-

Welcome to TAPS! Enhance the speed and accuracy of your Primavera P6 activity updating.

-

Give your team an easy to use report, even in the field with activities, resources or steps for scanning into TAPS.

-

TAPS supports the scanning of all activity types: unit, duration, and physical percentages.

-

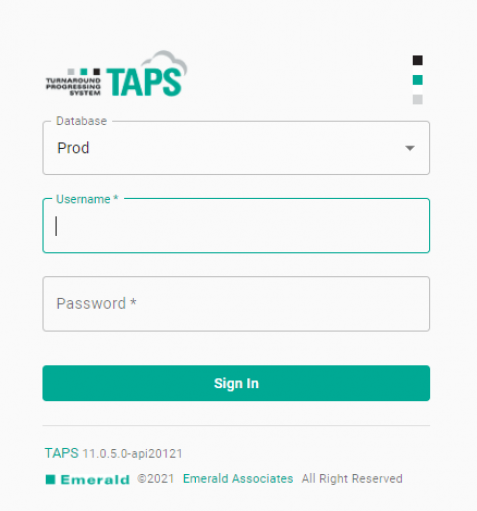

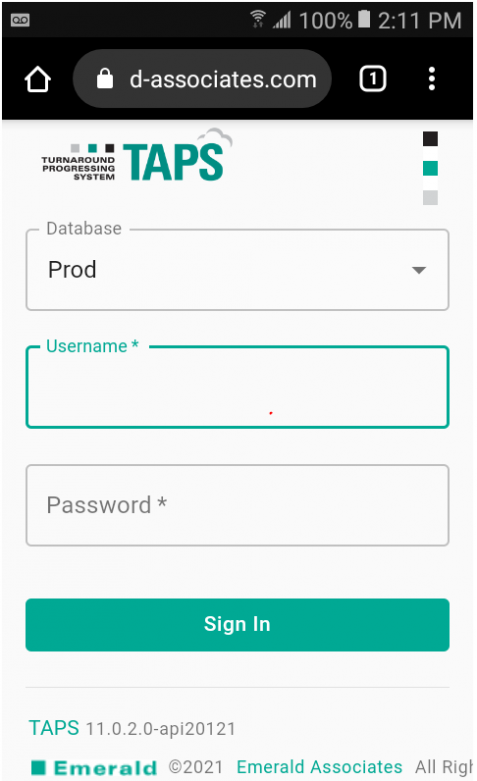

Verstion 11 log-in screen to TAPS.

-

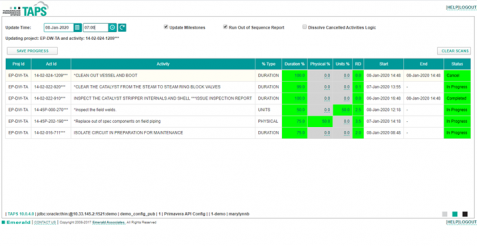

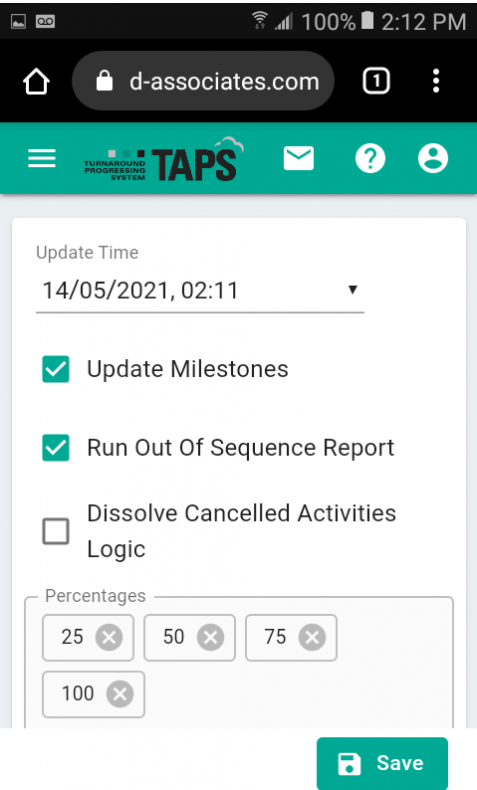

Set Update Date/Time and options and then scan in updates.

-

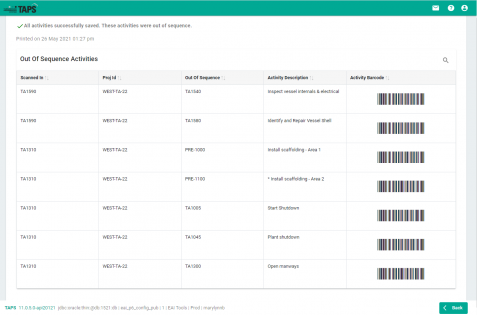

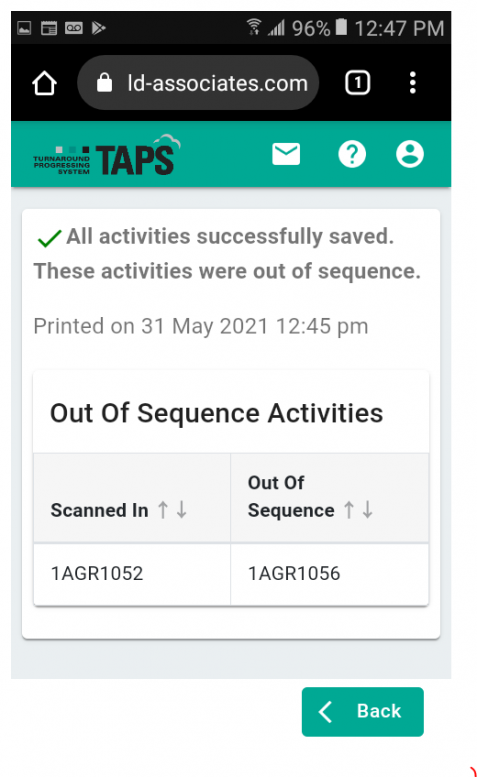

Submit updates and where applicable the out of sequence report is displayed.

-

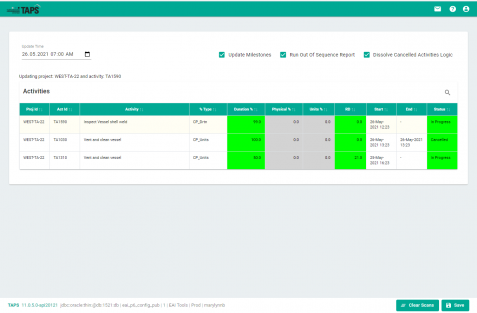

New for Version 11, TAPS is now available on mobile devices.

-

Set update date/time and set options. Customize Percentages is available on mobile only.

-

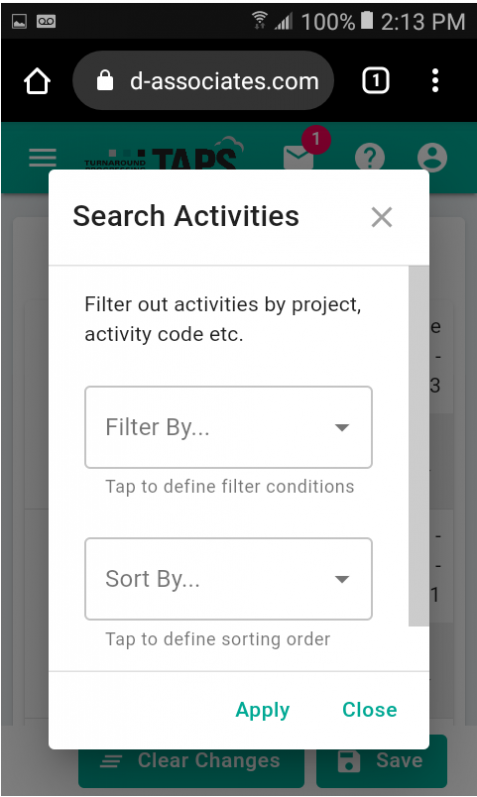

Set Filter/Sort Criteria required - apply/close.

-

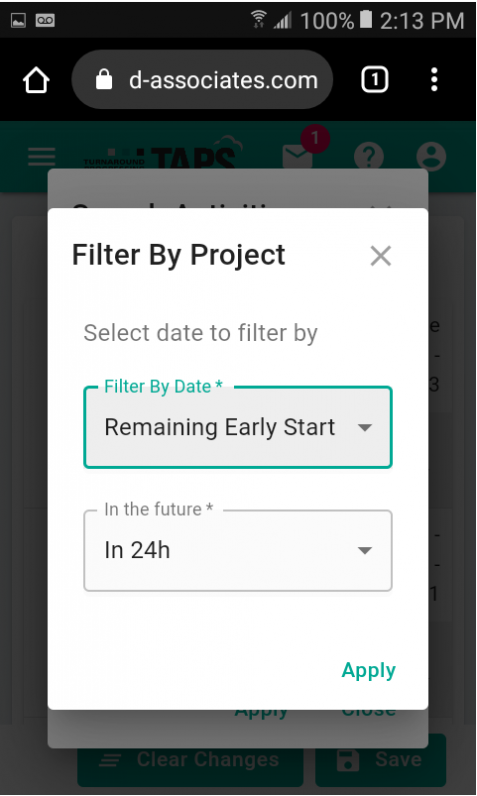

Set filter - this example is using Remaining Early Start in the next 24 hours.

-

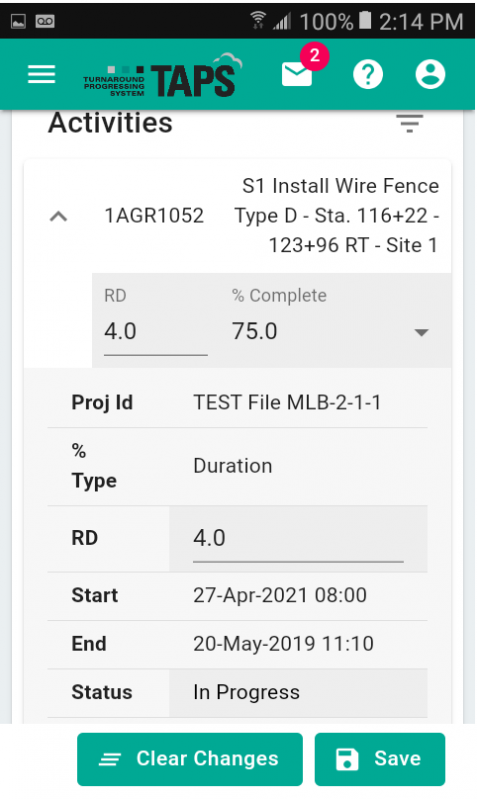

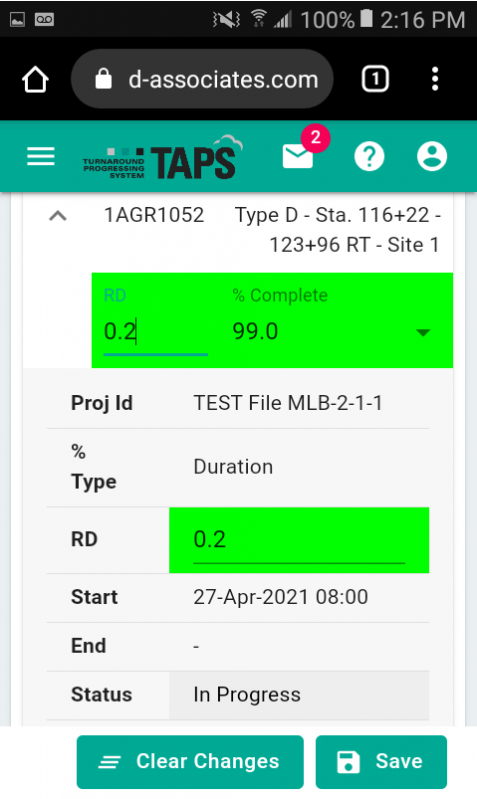

Expand the activity you want to update.

-

Enter Updates and Save.

-

The TAPS Out of Sequence Report will alert you if activity updates result in out of sequence progress.

Overview

Problem

Turnarounds, shutdowns and outages (TSOs) are high-profile, complex and time sensitive projects. With millions of dollars on the line each day in lost production revenue and labor costs, it is imperative that the TSOs be completed on schedule.

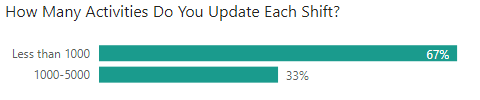

Typically, TSO field personnel keep notes of activity progress and report the progress to a scheduler. The scheduler then needs to enter that progress into Primavera. This process can be error-prone and consume large amounts of a skilled and expensive scheduling resource's time. That time could be much better spent analyzing the schedule, detecting issues, and developing mitigation strategies.

Solution

TAPS uses barcode scanning technology to eliminate the need for lengthy manual data entry when updating your Oracle Primavera P6 schedules. Simply use a barcode scanner to find, start and update any activity within the schedule in two fast scans.

With TAPS, time is no longer wasted searching for one activity among thousands in P6 and manually updating the start, finish and percent complete of each activity.

ROI

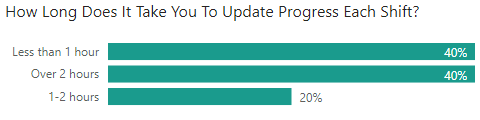

Emerald’s Turnaround Progressing System (TAPS) software increases your accuracy and cuts your shift statusing time by 75%. Shift reports are delivered on time, allowing management to make informed decisions based on timely insight into the current health of the TSO. Less experienced, less expensive resources can take on the job of updating tasks, while experienced schedulers are freed to analyze and act on the latest data. As a result, issues are avoided or mitigated before ballooning in to larger, more expensive problems, and the TSO remains on schedule.

News

TAPS v11 - New Release

Our latest version of the Turnaround Progressing System brings a fresh UI to mobile, activity searches and enhanced sorting and filtering capabilities.

Case Studies

Client Expands the Use of TAPS and P6-Loader to Their Western Division

Lubrication Company Implements TAPS

P6-Loader Used to Create a P6 Schedule

Large US Oil Company Implements P6-Loader and TAPS

TAPS - Reduce Stress, Improve Forecasting

TAPS at Suncor Energy

Large US Refinery Implements Emerald Tools

Back to top

Videos

Webinar Survey Results

Back to top

Blogs

Experience

Emerald Associates has implemented TAPS® for many clients including those in the oil & gas, petrochemical, agribusiness, and power generation industries. Here is what a few of our clients had to say:

“With virtually no training needed and a simple installation, TAPS is a cost effective way to boost my team’s productivity.

We can easily update a large detailed schedule which allows us to gain valuable visibility into performance and issues in real-time. This frees up schedulers time to analyze and mitigate issues before they balloon into larger more expensive and time consuming problems, which can make the difference in getting back into production on schedule.

TAPS has paid for itself several times over and I am extremely happy with this low-cost, real-time solution.”

- Kevin McAlpine, Turnaround Sr. Coordinator, NOVA Chemicals

“We have used this system for progressing Primavera scheduled activities for 3 turnarounds now and I and everyone who has used it for updating are most favorably impressed with the speed and accuracy achieved. What used to take an experienced user 1 ½ hours to 2 hours to update manually, now can be done in ½ an hour to ¾ of an hour and can be done accurately by a less experienced user.”

- Lead TA and Construction Scheduler, Suncor Energy

Clients currently using TAPS include:

- Yara - Saskferco Products Inc.

- Petro Canada

- Nova Chemicals Corporation

- Suncor Energy Inc.

- BP Products North America

- Nexen

- Enmax Energy

- Shell Canada

- Consumers Co-Operative Refineries Ltd.

- Agrium Inc.