Is the P6-QA Tool Only Relevant During Your Planning Phase? Absolutely Not!

Something we are asked is whether our P6-QA Tool is useful throughout the life cycle of your projects. Its use throughout the planning phase is obvious, of course; it helps with schedule development. Even after you’ve planned out your work though, the QA tool can help while you’re executing your plans. Let us examine a couple examples of how.

Keep in mind - it is beneficial to equip your team with the best tools for the job! Work Smarter, Not Harder!

SCENARIO 1

During the execution of our schedule, our team loads found work using P6-Loader. Our team didn’t omit any information required by the P6-Loader template. That’s definitely a good start, but just doing that isn’t checking specific schedule quality. The P6-QA tool removes the burden of manual schedule and business process analysis by automatically identifying deficiencies in Primavera P6 schedules based on scheduling best practices, industry standards such as the Defense Contract Management Agency’s (DCMA) 14-point assessment, and user introduced business process requirements.

Your schedule requires the ability to conduct its designated tasks. You are probably wondering 'what tasks'? For example, our schedule needs to reflect the execution plan, contain regular updates and provide the basis for project schedule reports.

Where does the P6-QA tool fit in? You might think you’re done after updating your schedule, but are your updates complete and correct? All execution schedules require regular updates and then analysis after the updates. Imagine having to manually review your updates every day. You’d lose a lot of valuable time! The P6-QA Tool can assist with finding errors that can occur in the information uploaded to your schedule and the information entered in updates.

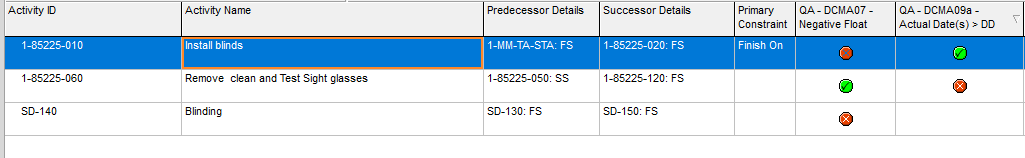

Imagine that during the update process, someone accidentally enters an incorrect completion date on an activity - this date is past the data date. In the P6-QA Tool, the negative float would automatically be flagged by DCMA07 in the P6-QA Tool, Negative Float Check.

Another update entry is a logic change required by a change in the execution plan for a couple of work packages. The change is not entered correctly, and therefore when the logic is entered it produces negative float in the schedule.

The logic entered produces negative float in the schedule.

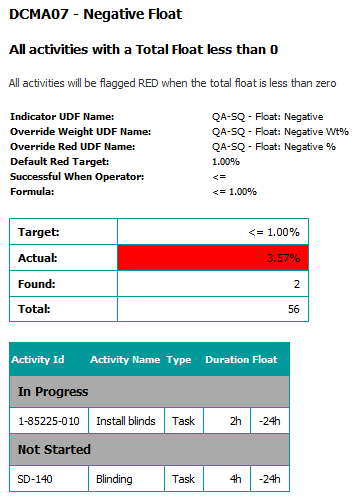

In the P6-QA Tool, the incorrect completion date would be automatically flagged by DCMA09a in the P6-QA Tool, Actual Date (s) After Project DD check.

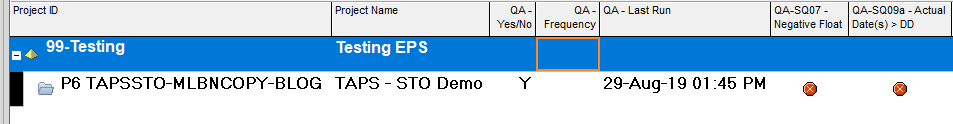

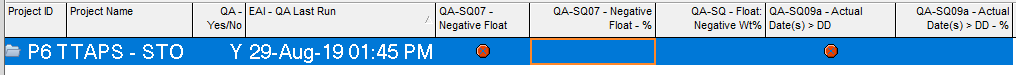

Here’s a project level display example:

Activity level example:

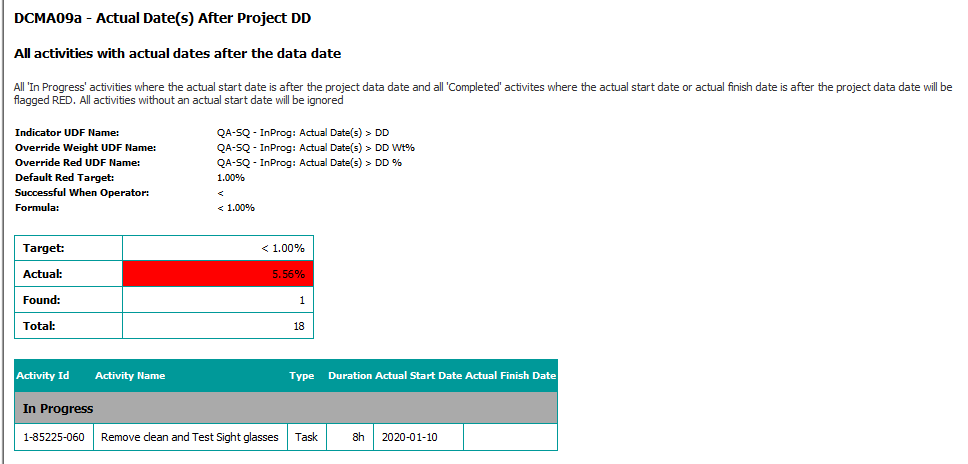

The desk top icons make locating activities you need to address quick and easy. You can sort, filter and use the icons in group and sort to create detailed layouts making identification of the checks to revisit expeditious.

Another one of our tools, the P6-Loader, creates reports in the project notebook. Some examples of report information from the two checks that did not pass the criteria are below. The report contains all the checks that have passed and failed.

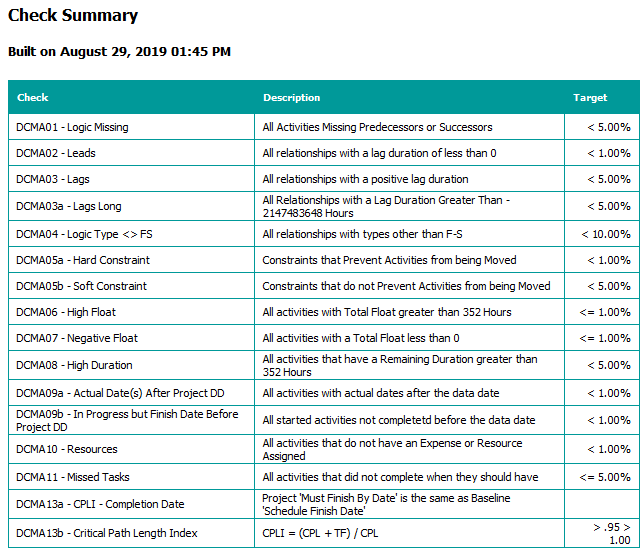

We looked at a couple of the list of DCMA checks the P6-QA Tool runs - there are plenty of other checks as well. The list below contains Business Process Validations run in the P6-QA Tool. These are some common issues, quickly highlighted by P6-QA Tool.

SCENARIO 2

Say your schedule is not progressing as planned - we need to create a couple of potential mitigation plans (what if scenarios). With the P6-QA tool, you can create copies of your schedule and test them with your proposed fixes. Once you’ve done this, you can address the findings to increase schedule quality maintenance. You set the parameters around the checks.

Above is a display of the parameter settings for the two checks we visited in scenario 1. (We used defaults to run scenario 1.) Being able to set your own parameters means you check your specific requirements, not a preset list of parameters you need to sort through later for applicability.

As you can see, the P6-QA tool remains relevant during your entire project. Empower your team with the best tools for the job with Emerald’s P6-QA Tool.

About the Author

Mary Lynn Backstrom, PMP, PMI-SP, PMI-BA – Implementation Specialist

Mary Lynn spent many years filling a variety of project controls duties such as planning, scheduling, analyzing, training and continuous improvement in the Aerospace Industry. Since joining Emerald in 2008, she has been a tremendous asset to the Emerald team. She has worked as a lead scheduler for turnarounds, led sessions for review and troubleshooting of scheduling and reporting, created and given custom training courses for clients, and is a sought after Primavera P6 trainer.

Mary Lynn enjoys some very diverse spare time activities. Along with a variety of outdoor activities such as gardening, she also enjoys making life size lawn ornaments for special holidays like Christmas. Mary Lynn is known for her participation in the community as well. You may have seen her walking in fundraisers in Edmonton and Calgary for the Cancer Society.