Your P6-QA metrics are now available in Power BI reports. You can also create custom reports via our P6-Reporter tool in your corporate dashboards. These reports include time based metrics to help you see where in your project these quality issues exist.

Written by James Andrade

Your P6-QA metrics are now available in Power BI reports. You can also create custom reports via our P6-Reporter tool in your corporate dashboards. These reports include time based metrics to help you see where in your project these quality issues exist.

New Features

-

New UDFs to show variances and calculated values - P6-QA may report that you have activities that are overdue for updating, but are they over by 2 days or 2 months? And what is your project's critical path length index (CPLI) exactly? Now you can view these metrics right in P6 to know how close they are to your target values.

-

Indicators for resource assignments - P6-QA has reported you have resource assignments that are missing roles, actuals or perhaps are over budget. In this release, we've added indicator UDFs. P6-QA populates them to let you find the affected resource assignment with ease.

-

P6-Reporter Ready - We've added custom tables to our P6-Reporter tool that neatly arrange your P6-QA data, including all of the inspection details, so it's ready to be put into the reporting software of your choice.

-

P6-QA statistics can now be pushed into time-based graphics. Being able to critique different portions of your schedule to get a much better idea of the risks and timing of those risks.

on Tuesday, 30 January 2024.

Posted in News, P6-QA

Your project schedule will be created in P6, and you are looking to provide the best schedule tools for your project team. What can you add to your team tool kit to assist the project team, address building the schedule, monitor schedule quality, utilize options for updating the schedule and make reporting quick and easy? Let’s look at a few examples for some food for thought.

Written by Mary Lynn Backstrom, PMP, PMI-SP, PMI-BA – Implementation Specialist

on Friday, 10 February 2023.

Posted in All Articles, P6-Loader, P6-QA, P6-Reporter, TAPS

Your P6-QA metrics are now available in Power BI reports. You can also create custom reports via our P6-Reporter tool.

Written by James Andrade - Integration Specialist

on Monday, 21 November 2022.

Posted in All Articles, P6-QA, P6-Reporter

Our latest version of P6-QA brings specific highlights to the GOA and Naval Air Scheduling quality standard metrics.

The latest version of the P6-QA tool from the team here at Emerald Associates brings with it specific highlights to the Government of Accountability (GOA) and Naval Air Scheduling quality standard metrics.

New Features

-

New quality metrics for GOA - Government of Accountability quality standards

-

New quality metrics notebooks for GOA - Government of Accountability quality standards

-

New quality metrics for Naval Air quality standards

-

New quality metrics notebooks for Naval Air quality standards

on Monday, 25 October 2021.

Posted in News, P6-QA

Something we are asked is whether our P6-QA Tool is useful throughout the life cycle of your projects. Its use throughout the planning phase is obvious, of course; it helps with schedule development. Even after you’ve planned out your work though, the QA tool can help while you’re executing your plans. Let us examine a couple examples of how.

Keep in mind - it is beneficial to equip your team with the best tools for the job! Work Smarter, Not Harder!

Written by Mary Lynn Backstrom, PMP, PMI-SP, PMI-BA – Implementation Specialist

on Monday, 20 July 2020.

Posted in All Articles, P6-QA

Before becoming an implementation specialist at Emerald Associates, I was a project manager and P6 administrator in a state government transportation agency for several years. I was responsible for managing 50-60 Primavera P6-EPPM (Web) project schedules and monitoring them to schedule completion. These projects were for the engineering and design of highway projects including tasks such as road maintenance, new road construction, bridge maintenance, and signals upgrades.

Written by Sue Fermelia - Implementation Specialist

on Monday, 08 July 2019.

Posted in All Articles, P6-QA

These reports require specific activity code assignments, and sometimes those are missing! Assigning these is time consuming and frustrating. But don't worry, help is available...with the P6-QA Tool!

Written by Mary Lynn Backstrom, PMP, PMI-SP, PMI-BA – Implementation Specialist

on Tuesday, 04 December 2018.

Posted in P6-QA

Wondering how exactly? After your updates have been entered into your schedule, run the P6-QA Tool. This tool performs many checks, including one to track Activities Completed Late.

Written by Mary Lynn Backstrom, PMP, PMI-SP, PMI-BA – Implementation Specialist

on Thursday, 29 November 2018.

Posted in P6-QA

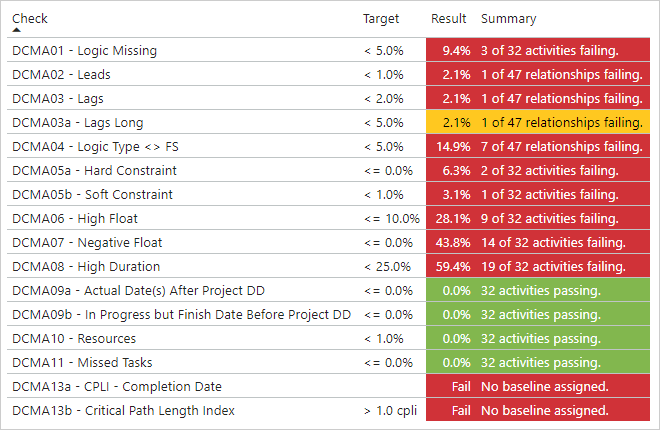

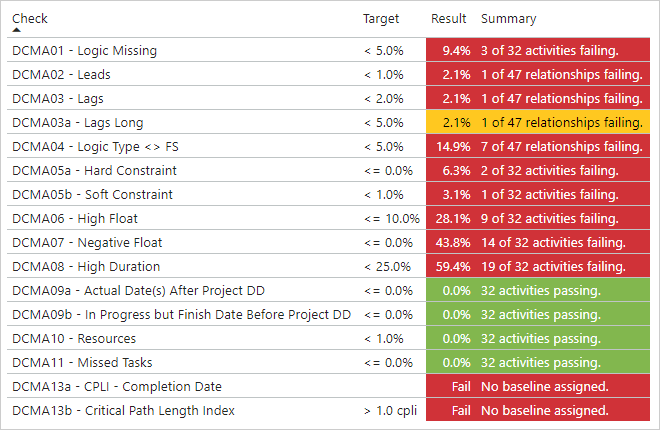

Manually wading through a schedule and looking for errors is time consuming and prone to human error. Not only that, it's boring. No one wants to do it, but you need to check your schedule for errors!

Even worse then working through your own schedule for errors, is slogging through a contractor's. When you don't know how they have built the schedule, it can take days to make sure things hold together. Some of our clients have several layouts, reports and even special access databases and outside tools to do this which is very time consuming, error prone and boring.

Written by Sue Fermelia - Implementation Specialist

on Wednesday, 09 May 2018.

Posted in All Articles, P6-QA, Primavera P6

Give Your New Schedulers A Head Start with the P6-QA Tool

Let’s help our new schedulers get up and running faster then ever before.

I love training up new schedulers. I've been a scheduling lead for years and always get a kick out of teaching new users best practices that I have learned the hard way.

Written by Mary Lynn Backstrom, PMP, PMI-SP, PMI-BA – Implementation Specialist

on Tuesday, 13 December 2016.

Posted in All Articles, P6-QA, Primavera P6

The P6-QA Tool Helps Answer This Loaded Question For A Construction Project

We are currently implementing Primavera P6 with a New York development company and I was asked the dreaded question “what do you think about the construction managers’ schedule”? Well this is a loaded question at the best of times because, although I am familiar with the project, I have not been involved in the contracting strategies and execution discussions.

Written by Nicole Jardin, P.Eng. - CEO

on Wednesday, 10 February 2016.

Posted in All Articles, P6-QA, Primavera P6